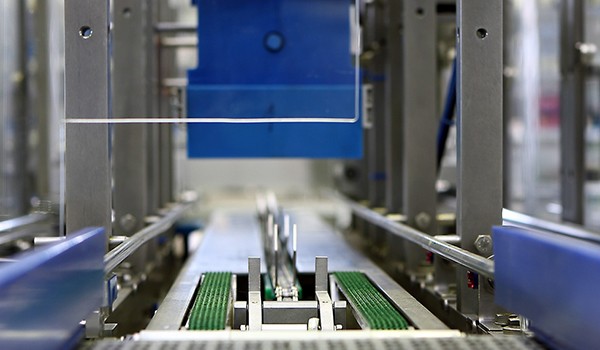

Carton sealer

Advantages and characteristics of our Carton Sealer:

- easy and fast format change

- ergonomic and easy operation, also for untrained staff

- rugged basic design

- high output (up to 100 cycles/min. with angle sealers / up to 200 cycles/min. with straight-on sealers)

- high availability

- operator friendly

- safe and gentle product handling

- easy change of guide belts free from tools

- low service cost and easy maintenance access

- suitable for operations in humid environments

Execution of our Carton Sealer:

- straight-on sealer (GV-HM or -HL) or angle sealer (WV-HM or -HL) available

- execution in stainless steel

- depending on version with servo or gear motors

- carton transfer by round belts without flights (straight-on sealer)

- carton transfer by flight chain (angle sealer)

- three flap closing units

- servo driven turning station between closing of the main lug and closing of the side lugs in the case of straight-on sealer

- central size changeover (height and width) by spindles and toothed raks

- format sizes (standard) up to approx. l 300 x w 180 x h 60mm

- lifting devices for upper belts (front flap closing area / end flap closing area) in the case of straight-on sealer

- hotmelt systems by Nordson, Robatech or Focke-Meler available

- safetly claddings in stainless steel and Macrolon

- switch cabinet in stainless steel

- control system: Siemens S7 or Schneider Elau, depending on version

- touch panel: Siemens

- optional: optical lug control after sealing

Products compatible with our Carton Sealer:

e.g. frozen food, vegetables, biscuits, sweets, ready meals, bakery products , bulk product, other pieced products and bagged products.

Method of operation of our Carton Sealer:

The WV (angle sealer) and the GV (straight-on sealer) are 3-lug sealers for cartons.

In the case of the WV the carton enters the machine with the short side leading as the top lid is being bent down. Afterwards glue (or hot air) is being applied to the long side to be sealed and the main lid is being closed. During the second step, after the 90° angle, glue or hot air is being applied to the short sides and the side lugs are being closed.

In the case of the straight-on sealer GV the closing of the main lug is similar, but as the speed is much higher so the cartons are being fed in continuously. After the 90° turning station the side lugs are being closed in a similar manner as in case of the WV.

Optionally a lug-control system is available to be located at the outfeed of the machine.