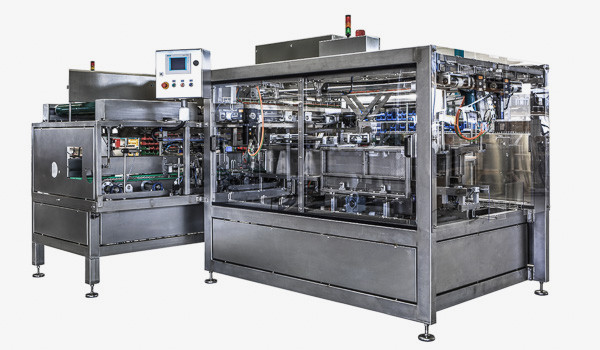

Case packer

Advantages and characteristics of our case packer:

- high dynamics and easy format change through individually controlled servo drives

- all adjustable units are equipped with either a scale or a display counter

- high capacity

- ergonomic and easy operation, also for untrained staff

- low maintenance cost and maintenance friendly

- available in stainless steel

- available for wet operation

- rugged basic design

- high flexibility concerning grouping and formats of the products

- safe sealing through hotmelt

- optional: top cover applicator for trays

Execution of our case packer:

- modular design of carton and/or tray handling, grouping and top cover applicator

- driven magazine for carton blanks, cases or blanks for top cover

- servo drives for case and tray handling, top cover applicator and grouping

- pneumatically driven lug folding

- hotmelt closure for all lugs

- hotmelt systems by Nordson, Robatech or Focke-Meler

- safety claddings in stainless steel and Makrolon

- switch cabinet optionally in stainless steel and in higher protection classes available

- touch panel: Siemens

Products compatible with our case packer:

e.g. frozen food, vegetables, biscuits, sweets, ready meals, bakery products , bulk product, other pieced products and bagged products.

Method of operation of our case packer:

The products to be packed are being grouped and then inserted into either a tray or a case. The tray may be sealed using a top cover. The cases may be pre-glued or erected from a flat bank.